testing burst seal strength|burst seal test : company method provides an indicator of the burst strength of a package, where the burst will normally occur in one or more areas of the seal. An indicator of the minimum burst strength may be of importance to the package manufacturer and end user in ensuring adequate package integrity. This test method cannot provide a measure of package seal uniformity. Play their other casual games on Poki: Rally Champion, Stupid Zombies 2, Castle Blocks, Idle Startup Tycoon, Idle Mining Empire, Idle Money Tree, Stupid Zombies, Classic Solitaire, Castle Fight With Buddies, Ping Pong, Sudoku Village, Tactical Squad, Super Bubble Shooter, Mine Sweeper, Mine Sweeper, 8 Ball Pool With Buddies, Mahjong .

{plog:ftitle_list}

Resultado da 23/01/2024. 12,00%. 4,9401. *A partir de 01/02/2006, o Índice Garantido passa a ser chamado Índice de Variação.

There are two basic types of seal strength testing addressed in ISO-11607: tensile strength testing and burst or creep (inflation) testing. Tensile seal strength testing (ASTM F88) uses a defined width sample (25.4mm) of the package seal perimeter.

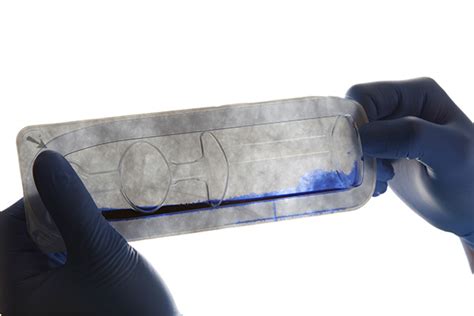

During burst testing, a package’s internal pressure is increased until it ruptures. This can be either a materials failure or seal failure. Because burst testing is a destructive test, the intact test sample cannot be recovered following the testing process. Burst testing is accomplished with the use of compressed air.Seal strength testing evaluates the mechanical strength of the seal, assuring proper bonding to maintain package integrity throughout the life of the package. Here we address two basic typle of seal strength testing: tensile strength testing (ASTM F88) and burst or crepp testing (ASTM F1140 & ASTM FStrength tests include seal peel and burst testing. Integrity tests include bubble emission and dye migration, however additional packaging testing for integrity are also available. Our packaging testing is done in compliance with .

method provides an indicator of the burst strength of a package, where the burst will normally occur in one or more areas of the seal. An indicator of the minimum burst strength may be of importance to the package manufacturer and end user in ensuring adequate package integrity. This test method cannot provide a measure of package seal uniformity.

C660M Leak and Seal Strength Tester can used for leak test, burst test and creep test of finished packages and three-side sealed packages, based on ISO 11067, ASTM F1140 & ASTM F2054. Google Reviews. . Heat-seal strength test for cap films of .The burst test function automatically inflates the test sample until seal failure occurs. The creep test feature checks package seals under sustained pressure. The creep-to-burst feature sequentially checks minimum required seal strength and maximum pressure at burst. The operator sets test variables using easyBurst strength testing quickly evaluates package seal strength during the transportation life cycle. More specifically, burst strength testing assesses the integrity of a seal when a package is exposed to a uniform pressure differential until the weakest part of the seal is separated.

Burst Test: Dye Migration. Microbial challenge: Creep Test. Dye Immersion: . post aging testing. Accelerated Aging – post aging testing. Baseline Testing (strength, integrity, microbial) Distribution testing. Final Product – post sterilization. Test Methods. ISO 11607 • Any test method used needs to be validated for . •Testing both .Although no universal mathematical relationship has been defined between tensile and inflation seal-strength tests, research on pouches shows a correlation between restrained- plate inflation testing and tensile testing in locating the minimum seal-strength area. In a burst test, a package is inflated at a uniform pressure and flow rate until .

ASTM F88 Seal Strength; ASTM F1140 Burst Test (Unrestrained) ASTM F1886 Determining Integrity of Seals by Visual Inspection; ASTM F2054 Burst Test (Restrained) ASTM F2096 Gross Leak detection (Bubble test) These test methods fall under the general heading of Tensile Tests that are used for assessing the inherent sealing qualities of flexible .

Burst strength test. With internal pressure resistance as the measurement to check all seals, apply uniform pressure, under designated test conditions, to a level of not less than specified for a .During the transportation life cycle, burst strength testing swiftly assesses the strength of the package seal. When a package is exposed to a constant pressure differential until the weakest piece of the seal separates, burst strength testing .Both methods are suitable for measuring seal strength. ASTM standards provide for several test methods for burst testing, including dynamic, static, creep, and creep to fail tests. These tests are used to measure the strength of medical device package sterile barrier systems as well as characterize which seal within a package system is the . An approximation of the stress created by uniform seal geometry around the package perimeter (P = internal pressure, R = radius, Fy = forces perpendicular to the seal, and Fx = forces parallel to the seal). The use of restraining plate tests as part of the measuring process for burst seal strength and creep resistance tests is expected to grow.

We begin with seal strength tests, followed by tests for hermeticity, and conclude with a summary chart for easy comparison. 1. Peel Strength Test . outcomes depend on package size and geometry—a given pressure level .

sterile seal strength testing

Burst testing measures the strength of fabrics and materials, by providing pressure (force) on the material from all directions equally at the same time, to measure the conditions that will cause it to rupture. When a fabric 'fails' due to .

the life of the package. The Seal Strength also provides assurance of control of the “peelable” characteristic of the package. ISO-11607 refers to two methods which may be used to determine seal strength, tensile strength testing and burst or creep pressure (inflation) testing. Tensile Seal Strength Testing (ASTM F88) uses a defined Note that the burst test method does not give you a way to measure the strength of a particular seal on the package, since all package seals experience the same force until the weakest spot on the weakest seal eventually gives way. Therefore, care should be taken to consider whether this method is appropriate for your application. Consider Seal .It is important to note that this test’s purpose is for the seal’s burst strength. ASTM F2054 cannot make any determinations of overall package strength or areas of the package that touch the restraining plates. However, burst leak integrity testing can be used to evaluate seal strength during manufacturing and various points of distribution.

ASTM F88 is a test method in which packaging engineers can define seal strength requirements, like a minimum seal strength. We define what minimum seal strength is by conducting a DOE to find out what is the best recipe for seal strength and visual score. Conducting a DOE allows us to figure out which factor has a greater effect on seal .

AN-PTPS-1004-Testing Seal Burst Strength of Porous Med Pkg-0424-1.3 Traditional methods for testing seal burst strength are time-consuming and imprecise. The mechanical seal burst strength must withstand the rigors of production, sterilization, distribution and storage, yet be easily opened by healthcare professionals. Our professional opinion is to go with F88 for your medical devices packaging validation and supplement seal strength with burst testing. We typically see that option when clients are looking for a simpler testing process for a startup or in-process testing. ASTM F88 requires a bit of finesse to execute properly (i.e. straight cuts, good .In addition to burst strength, this UTM can test the coefficient of friction, tensile, elongation, seal strength and puncture strength with the appropriate grips and fixtures. Rycolab Burst Testers RL-BT-A (Paper & Paperboard): The Rycolab Burst Tester (RL-BT-A) uses the MULLEN method to measure the burst strength of paper materials.Knowing the seal strength can prevent leaks, contamination, and other problems that may arise in the product’s lifespan. Additionally, retailers and consumers rely on packaging to protect products during transportation and handling, making it essential to test the seal strength. Overall, tensile testing seal strength ensures that the product .

Measuring seal strength and carrying out pressure leak tests are important prerequisites to delivering strong and lasting packaging that have a low risk of bursting under pressure. For additional testing options within the Lippke product line, you may consider the Lippke VC 1400 and the Multicheck 2 . Seal strength testing is a crucial quality control step in the medical device packaging field, ensuring that seals meet the high standards necessary for the healthcare industry. . Burst testing; Tensile testing; Peel Testing. Peel testing is a widely used method in the assessment of seal strength for various types of packaging, especially .Burst Strength Package Integrity Testing is a process used to evaluate seal strength when a package is exposed to a consistent pressure differential. This test, which is often employed by the medical, pharmaceutical, biotechnology, and food packaging industries, helps ensure package integrity and minimize the cost of poor packaging.

sterile barrier seal strength testing

6 de dez. de 2022 · PROBLEMA SOBRE PORCENTAGEM.Num jogo de futebol, compareceram 20.538 torcedores nas arquibancadas, 12.100 nas cadeiras numeradas e 32.070 nas gerais. Nesse jo.

testing burst seal strength|burst seal test